Baseline Environmental Impact Analysis Completed for SiLEAN Technology

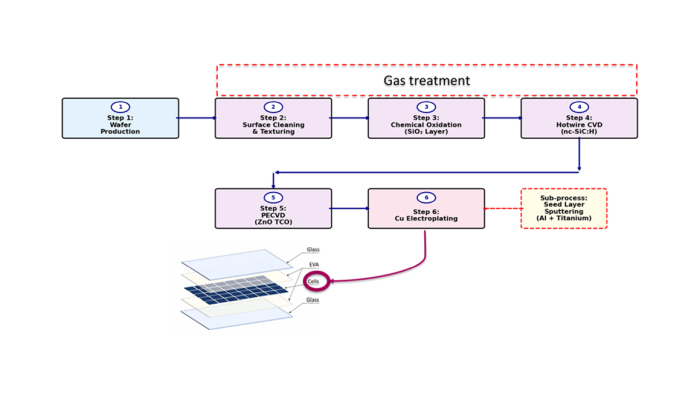

The SiLEAN consortium has completed an important milestone with the establishment of the baseline environmental impact analysis for its photovoltaic technology. Using the Life Cycle Assessment (LCA) approach, researchers at TUD evaluated the cradle-to-gate environmental impacts of producing one square meter of a SiLEAN solar module. The study follows the Product Environmental Footprint methodology and is based on detailed, process-level data covering steps such as surface cleaning, chemical oxidation, deposition processes, and electroplating.

The results show that the most significant contributions to the overall environmental footprint are linked to climate change (28%), depletion of minerals and metals (19%), and depletion of non-renewable energy resources (17%). Wafer production emerges as the dominant contributor across many categories, particularly in relation to climate change and particulate matter. Within this phase, emissions such as CO₂, responsible for 91% of the climate impact, and sulfur dioxide play a critical role.

Interestingly, SiLEAN-specific process steps account for only 6% of the total baseline impact. Within that share, the formation of copper metallization, the deposition of nc-SiC:H, and the creation of ZnO layers are identified as the most influential contributors. The analysis also highlights that electricity consumption and compressed air are critical contributors, underscoring the importance of energy-efficient production and clean energy sourcing. This sensitivity to the energy mix will be a key consideration as processes move toward industrial scale.

The baseline results provide a reference point against which future optimizations in SiLEAN can be measured, helping ensure that advances in performance go hand-in-hand with reduced environmental impact.

More updates will follow as the project continues work on lowering resource use and improving sustainability across the full production chain.